When it comes to gifts for your customers or clients, promotional products are often the answer for most businesses. Unlike flyers, cards, stickers or other paper products, promotional items use different printing methods to get your artwork printed on top of their surface. This is due to the material they use, unlike paper that absorbs ink easily, promotional items consist of various materials that may not absorb ink like papers do.

Here at gogoprint, we offer a wide variety of promotional products with distinctive printing methods. As for details of these printing techniques, we will get it covered in this article, so read on!

Silk-Screen

This 100 year old printing method is popular among many companies. There are various kinds of silk-screen printing, depending on the objective and the process of the printing. Silk-screen printing uses a mesh based stencil to apply ink onto a substrate such as fabrics, posters, stickers, vinyl, and even wood. First, a frame is created along with the design, then the frame is placed on top of the product. By using a scraper, the colored ink is screened, meaning the ink is transferred into the product this way. Each layer consists of one color, up to a maximum of four colors. After a layer is applied, the frame is then left to dry and reused again for another application.

Silk screen requires spot color to print. Examples of our promotional items using the silk-screen printing method are non woven bags, Pens, notebooks and many more!

Pad Printing

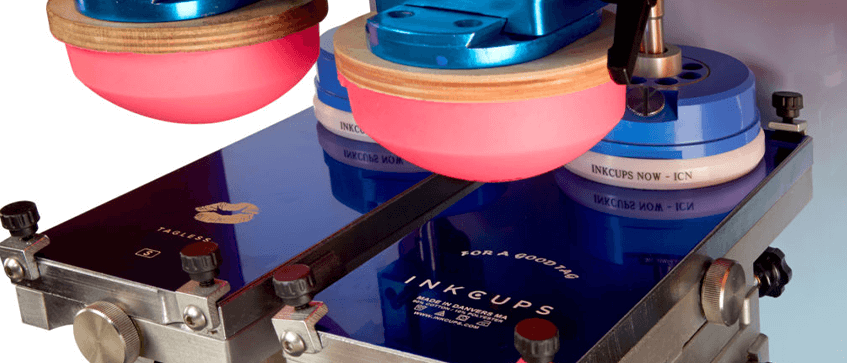

Credits: Inkcups

This printing method (also called tampography) is a process that can transfer 2 dimensional graphics onto objects. PAD Printing is unique in that it is able to print on products with uneven surfaces, which includes flat, spherical, textured, concave and convex surfaces. As for the process, the graphic is basically etched onto a flat printing plate, then the plate itself is filled with ink. A chemical resistant silicone pad is then used to transfer the ink from the plate onto the product. It is through the use of silicone pads that gives this printing technique its name. Nowadays, PAD printing is widely used in many industries.

Pad printing requires spot color to print. Our promotional products such as pens and bottles also use this printing technology as well.

Heat Transfer

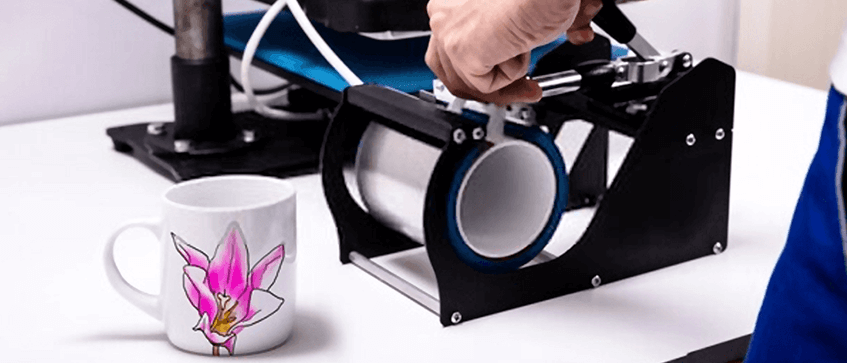

Credits: Crafts Selection

Heat transfer printing is another name for thermal transfer printing. In this method, the design is first printed on sublimation paper using sublimation ink, which then is transferred onto the surface using pressure at high temperatures, thus the term “heat transfer”. After the printing, the product is then allowed to cool down. Heat transfer printing normally leaves a permanent, vivid image with a soft-to-the-hand feel.

Heat transfer only requires normal CMYK (full color) to print. Heat transfer printing method is commonly used in t-shirts, ceramic mugs, lanyards,

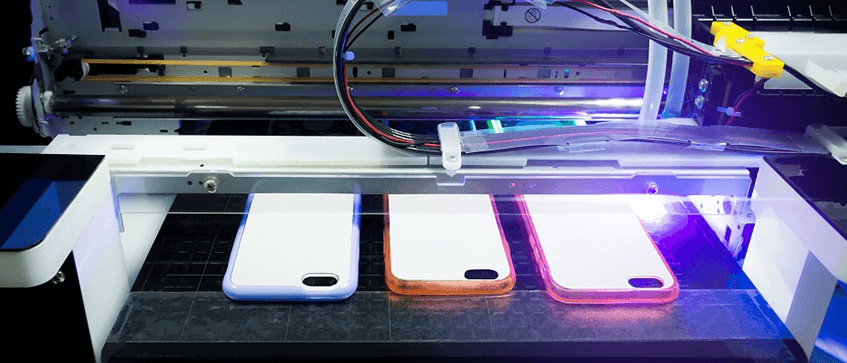

UV Printing

This method is a type of digital printing that utilizes ultraviolet lights to dry up ink during the printing process. While the printer produces ink on the surface of the object (also called a "substrate"), the specially made UV lights will follow close behind, drying the ink immediately. This method was first developed for quick-dry gel nail polishes. It was then expanded into other industries around the world.

Just like heat transfer, UV printing only requires normal CMYK (full color) to print. Our custom white card USB flash drive uses this printing technique.

Laser Engraving

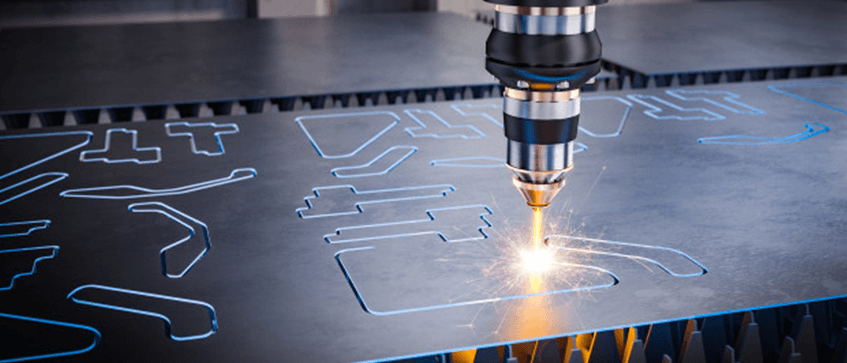

Laser Engraving (also called Laser Etching) is a Subtractive Manufacturing technique that utilizes a laser beam to adjust a surface of an object. As for how it is done, the laser is used to produce high temperatures, which will vaporize the matter, thus exposing cavities that will “carve” out the image. The process is swift and quick, as each pulse of the laser will remove parts of the material. The depth of the marks can be determined by how many times the laser beam goes through on the surface.

As the name suggests, laser engraving requires no ink when printing. In Gogoprint, we use this printing method for our powerbanks, Hot Foil Business Cards!

Conclusion

We hope this article can be an eye-opener for the printing techniques we used and also by most printing industries. Using a broad range of different materials and formats, we guarantee to find a way to best print your product. So whether you want to print pens or tote bags for private use or want to purchase a broad range of different products to promote your business, we process jobs of all sizes like you want them.

With that in mind, why not try us out with these printing techniques and be surprised at the results! :)

Thai / Thai

Thai / Thai  English / English

English / English